Introduction

Cold process soap making has become increasingly popular among those who wish to create their own natural skincare products. This technique not only allows for complete customization but also ensures that users are aware of every ingredient that goes into their soap. As consumers shift towards more eco-friendly and natural options, cold process soap making provides an appealing alternative to commercially produced soaps, which often contain synthetic ingredients and preservatives.

This article will cover the fundamental aspects of cold process soap making, explore key trends in natural skincare, and offer tips on how to successfully create your own soap at home. From choosing sustainable ingredients to understanding the curing process, readers will gain a comprehensive understanding of the craft. Let’s dive into the fascinating world of cold process soap making.

The Basics of Cold Process Soap Making

Cold process soap making is built upon the foundational chemical reaction known as saponification, which occurs when fats or oils are mixed with a lye solution. This method differs from hot process soap making, wherein heat is applied to speed up saponification. In the cold process, the soap is allowed to undergo this reaction at room temperature, resulting in a milder and often more skin-friendly product.

To get started, one needs several essential tools and ingredients. You’ll need a scale for accurate measurements, a thermometer, mixing utensils, safety gear like gloves and goggles, and of course, your chosen oils and lye. It is critical to measure the ingredients accurately, as even slight deviations can affect the final product.

Step-by-Step Guide to Making Cold Process Soap

- Preparation: Begin by gathering all necessary ingredients and tools. Ensure that your workspace is clean and organized to prevent contamination.

- Safety First: Wear gloves and goggles, as lye is caustic and can cause burns. Set up your lye solution by carefully mixing lye with water in a well-ventilated area. Always add lye to water, never the other way around, to avoid dangerous reactions.

- Mixing Oils: Measure and melt your solid oils if necessary. Then, combine all oils in a large mixing bowl and let them cool to the right temperature, typically between 95°F and 105°F.

- Combining Lye and Oils: Once both the lye solution and oils are at similar temperatures, slowly pour the lye solution into the oils. Use a stick blender to mix until reaching “trace,” which looks like a thick pudding.

- Adding Additives: This is the stage to add any essential oils, colorants, or other additives like exfoliants or botanicals. Stir to combine evenly.

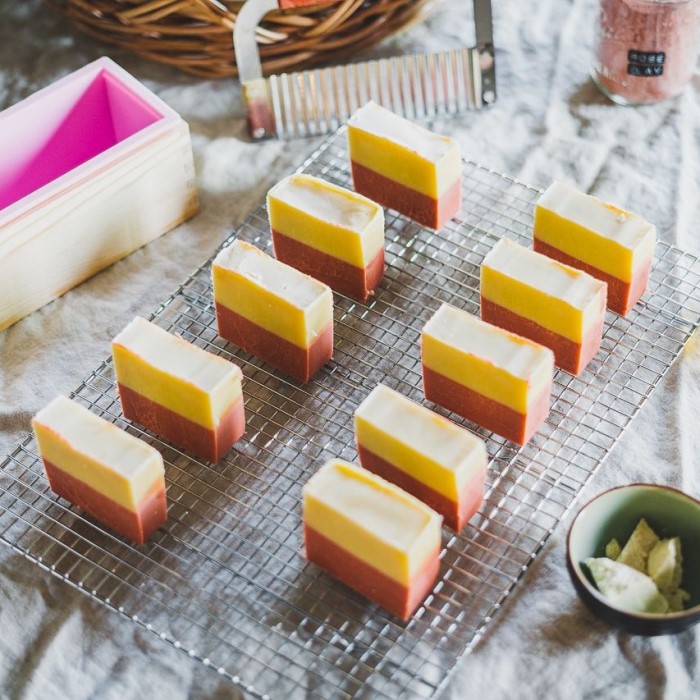

- Pouring into Molds: Pour the mixture into prepared molds. Tap lightly to remove air bubbles.

- Curing: Cover the molds and allow them to sit for 24-48 hours. After removing the soap from the mold, let it cure for 4-6 weeks to complete the saponification process and evaporate excess moisture. This makes the soap gentler on the skin.

- Cutting and Storing: Once cured, cut the soap into bars and store them in a cool, dry place.

Popular Ingredients for Cold Process Soap

In recent years, the choice of ingredients in cold process soap making has shifted towards more sustainable and skin-friendly options. Below are some ingredients that have gained popularity:

Olive Oil

- Moisturizing Properties: Olive oil is renowned for its excellent moisturizing capabilities, making it ideal for creating skin-friendly products.

- Gentle on Skin: Its soft and gentle nature is particularly beneficial for individuals with sensitive skin or skin conditions, as it helps to hydrate and soothe without causing irritation.

- Nutritional Benefits: Rich in antioxidants and vitamins, olive oil also nourishes the skin, promoting overall health and radiance.

- Saponification Benefits: In the soap-making process, olive oil contributes to a mild and gentle lather, making it suitable for daily use and for maintaining skin health.

Coconut Oil

- Rich Lather Production: Coconut oil is widely recognized for its ability to produce a luxurious, foamy lather that enhances the overall washing experience.

- Versatile Ingredient: Commonly included in many soap recipes, it provides structure and contributes to the soap’s hardness, allowing bars to last longer.

- Balancing Act: While coconut oil is beneficial, it can be overly drying when used in excess; therefore, it is typically blended with softer oils, such as olive or almond oil, to maintain skin hydration.

- Antimicrobial Properties: Beyond lathering, coconut oil possesses natural antimicrobial properties, which can help in keeping the skin clear and healthy.

Avocado Oil

- Nutrient-Rich: Avocado oil is packed with essential fatty acids, vitamins A, D, and E, making it a powerhouse for nourishing the skin.

- Exceptional Moisturization: Its unique composition lends exceptional moisturizing properties, making it an excellent choice for dry or mature skin types.

- Popular Among Artisans: Many soap makers favor avocado oil for its ability to provide a luxurious feel to soap, as it results in a creamy, nourishing bar.

- Skin Healing Qualities: Moreover, avocado oil has been known to aid in healing and repairing the skin due to its anti-inflammatory properties.

Essential Oils

- Natural Fragrance: Essential oils serve as natural fragrance enhancers in soaps, offering a delightful sensory experience without synthetic additives.

- Therapeutic Benefits: Beyond scent, many essential oils possess therapeutic properties, such as calming effects from lavender and chamomile, which promote relaxation. Others, like tea tree oil, offer antibacterial and antifungal benefits that can support skin health.

- Customization: Soap makers can experiment with various essential oil combinations, allowing them to create unique scents and therapeutic blends tailored to specific needs.

- Emotional Wellness: The aromatic properties of essential oils can also contribute to emotional well-being, making bathing a more holistic experience.

Botanicals and Clays

- Visual Appeal: Ingredients such as dried flowers, herbs, and clays not only enhance the soap’s visual aesthetic but can also add intriguing textures, making each bar unique.

- Skin Benefits: Botanicals like oatmeal can provide gentle exfoliation, while clays can help absorb impurities and excess oils from the skin, contributing to a clearer complexion.

- Natural Exfoliants: Some botanicals can act as natural exfoliants, helping to slough off dead skin cells and promote a smoother skin surface.

- Artisan Touch: The inclusion of botanicals and clays allows artisans to personalize their soap further, creating signature blends that reflect their creativity and craftsmanship.

Embracing Sustainable Practices

As the global focus on sustainability grows, many soap makers are beginning to embrace eco-friendly practices. This includes sourcing organic ingredients and minimizing waste. For instance, some artisans collect unused scraps from previous batches and incorporate them into new recipes, creating a visually intriguing mixed soap.

In addition to ingredient sourcing, packaging considerations are crucial. Biodegradable or recyclable materials are favored by consumers who seek to reduce their environmental impact. By employing eco-conscious practices, cold process soap makers align with modern values of sustainability and health.

Addressing Common Challenges

While cold process soap making is an enjoyable and rewarding craft, it does come with certain challenges. For one, achieving the perfect “trace”—the moment when the mixture thickens enough to hold a design—can be difficult. It takes practice to identify the right consistency, but the results are worth the effort.

Another common issue is dealing with lye correctly. Mistakes in measuring lye can lead to harsh soap. Therefore, always double-check calculations, and consider using a soap calculator specific to cold process methods to ensure your ingredients are balanced.

Frequently Asked Questions

How long does it take to cold process soap?

The entire cold process soap making timeline can vary. It generally takes 24 to 48 hours for the soap to set in the mold. After that, a cure time of 4 to 6 weeks is essential for the soap to become mild and ready for use.

What are the best ingredients for cold process soap?

The best ingredients commonly include olive oil, coconut oil, avocado oil, and various essential oils for fragrance. Many soap makers also use natural colorants and botanicals to enhance the soap’s visual appeal and benefits.

What are the cons of cold process soap?

The main disadvantages include the need for careful measurement and handling of lye, which can be hazardous if not treated properly. Additionally, the longer curing time may be off-putting for those wanting an immediate product.

Which is better, hot or cold process soap?

The choice between hot and cold process soap depends largely on personal preferences. Cold process soap allows for a greater variety of textures and blends and often results in a more gentle product, while hot process soap can be used more quickly as it minimizes the cure time.

The Future of Cold Process Soap Making

Looking forward, cold process soap making stands ready to expand further. As natural skincare continues to gain traction, the demand for bespoke, handcrafted products will likely grow. Many consumers are seeking to support local artisans, which benefits the cold process soap maker adhering to sustainable practices.

Communities formed around soap making are also on the rise. Online platforms provide ample resources for beginners and experienced crafters alike, offering everything from recipes to support groups. This is creating a vibrant culture around handmade soaps.

Conclusion: Join the Cold Process Soap Making Revolution

Cold process soap making is not just a craft—it’s a movement towards mindful and sustainable living. By making soap at home, you can ensure that you are using quality, natural ingredients, benefiting both your skin and the environment. As we witness more individuals embracing this craft, the future of cold process soap making looks promising.

Whether you are an experienced soap maker or just considering starting this exciting journey, there is always room for creativity, experimentation, and learning. So grab your ingredients, gather your tools, and begin crafting beautiful, natural soap that reflects your personal values and style. Embrace the art of cold process soap making and contribute to a more sustainable future.